Cost Optimization Maturity Model

By Craig Theisen

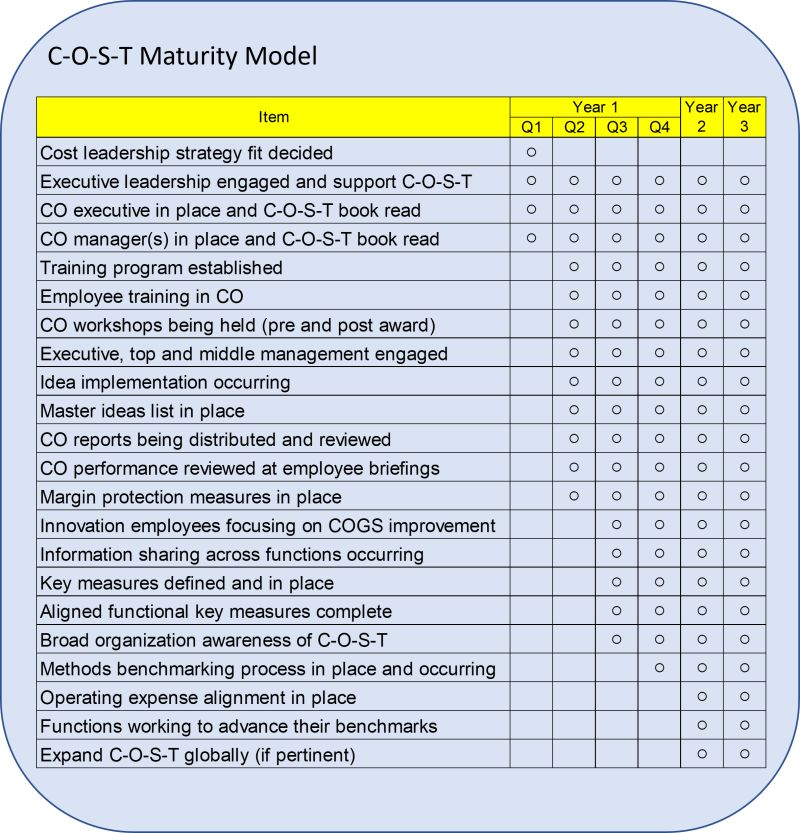

Let’s say your company wants to install a new capability. Perhaps they need to improve costs and would like to build a continuous improvement capability. Developing a maturity model and implementing the identified steps is an effective way to build the capability.

A maturity model identifies capabilities that are needed, and the time frame in which they are wanted, to enable a new, overall capability.

In building the continuous improvement capability, examples of things the company may want to put in place include:

1. Executive leadership buy-in

2. Continuous improvement leader

3. Continuous improvement project leaders

4. Company training on how to make continuous improvement.

5. A budget for personnel and activity

6. Manufacturing plant engagement in continuous improvement.

7. A list of potential projects

8. Key measures to track outcomes.

9. Customer interface strategy

10. Global expansion of continuous improvement methodology

If the company wants steps 1-10 to be in place within a year, each step in the maturity model would be timed to fit within the year.

The maturity model considers the qualitative side of implementing something new. For example, with executive buy-in, 3 of 5 executives may be totally on board, 1 is neutral and 1 is against it. If the company desired more buy-in, they could keep working on that element of the model.

The maturity model does not track quantitative data such as the amount of money saved from continuous improvement. Quantitative data will come from the key measures, item 8, that will be put into place.

The illustration shows the maturity model for the Cost Optimization System and Technique, C-O-S-T for short. The illustration is from chapter 29 of the book “C-O-S-T” which is available at Amazon (https://amzn.to/3vtP9Df) and other book retailers.

When installing a new capability in a company, a maturity model is a great way to plan out and execute it.